Xypex Treatment of Pile Caps and Pile Supported Mat Slabs

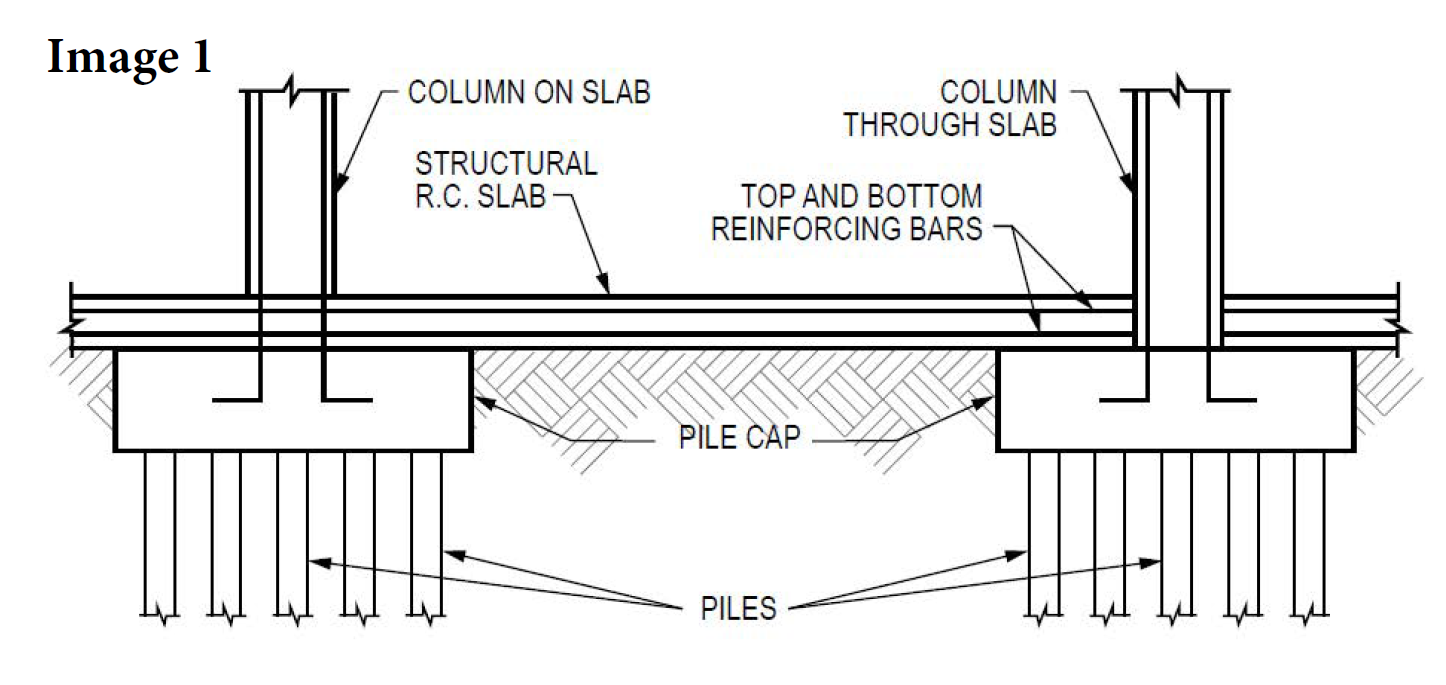

Piles are a commonly used foundation for the support of structures. Groups of piles will often be combined into pile caps. The lowest level slab is cast on top of the pile caps to create a level uninterrupted surface. Load bearing columns typically align with the pile caps and either sit on the slab or extend through the slab onto the pile caps itself. The illustration on the right ( Image 1 ) shows both of these assembles.

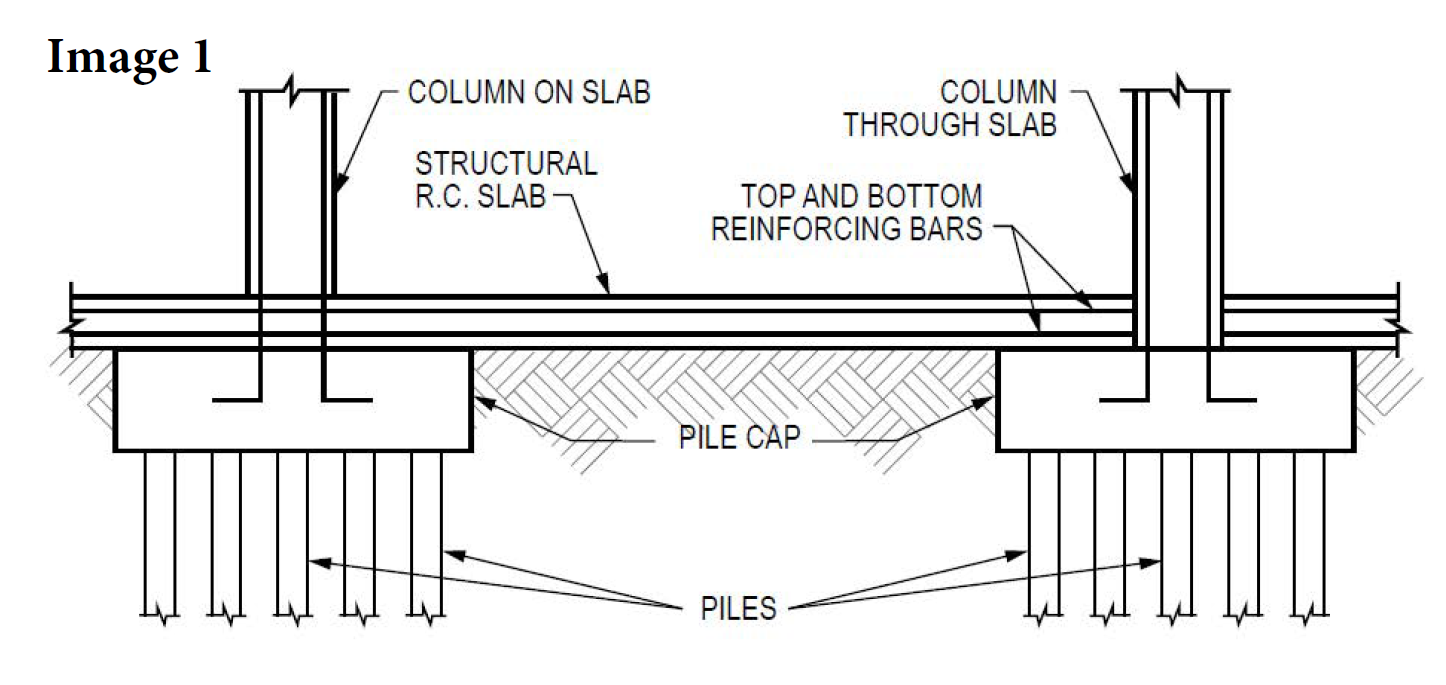

Xypex products are often used in the pile caps to waterproof the pile cap assembly and stop water from wicking up and through the slab / column which can create moisture problems in the structure. the use of Xypex Admix in the pile caps is an easy and cost effective way to create a capillary break, prevent water from wicking upward, and to waterproof the joints and cracks in the pile cap assembly. The use of Xypex jointing details at the columns and walls along with Xypex Admix in the slab and walls will create a fully waterproof below grade space eliminating the need for a membrane or other waterproofing systems. An alternate method to waterproof the pile caps themselves is to apply Xypex Concentrate at a rate of 2 lb/yd3 (1 kg/m2) to the surface of the pile cap. This coating method is often used when other types of waterproofing systems are installed for the slab and designers wish to terminate these systems on the pile cap instead of trying to install the membrane around every column and all the congested reinforcing steel that extends out of the pile cap.

The Xypex Admix and Xypex coating methods for treating the pile caps are illustrated to the right (Image 2). A third method which is used to create a capillary break in the pile themselves is also illustrated. In this assembly, the top approximately 3′ (1 m) of the pile concrete is treated with Xypex Admix thus moving the capillary break down into piles themselves.

Need help with your waterproofing challenge?

Get in touch